OEM Laboratory and Safety Clothing Solutions for Enhanced Protection and Performance in Work Environments

The Importance of OEM Lab and Safety Clothing in Modern Manufacturing

In today’s fast-paced manufacturing environment, the integration of advanced technologies and stringent safety protocols has become paramount. One of the crucial components of this paradigm shift is the role of OEM (Original Equipment Manufacturer) labs and the importance of safety clothing. These elements not only ensure compliance with industry standards but also significantly enhance worker safety and operational efficiency.

OEM labs play a pivotal role in the manufacturing process. They are specialized facilities where products are designed, tested, and validated before they reach the market. By working closely with manufacturers, OEM labs ensure that their products meet the required specifications and regulatory standards. This collaboration fosters innovation, as companies utilize the latest technology and insights generated from these labs to enhance product quality and performance.

The Importance of OEM Lab and Safety Clothing in Modern Manufacturing

Moreover, the design and functionality of safety clothing have evolved significantly in recent years. Manufacturers are now focusing on ergonomics, ensuring that protective gear allows for mobility and comfort while still providing adequate protection. Modern safety clothing often incorporates moisture-wicking fabrics, ventilation systems, and reflective materials, enhancing both safety and comfort for workers in challenging environments.

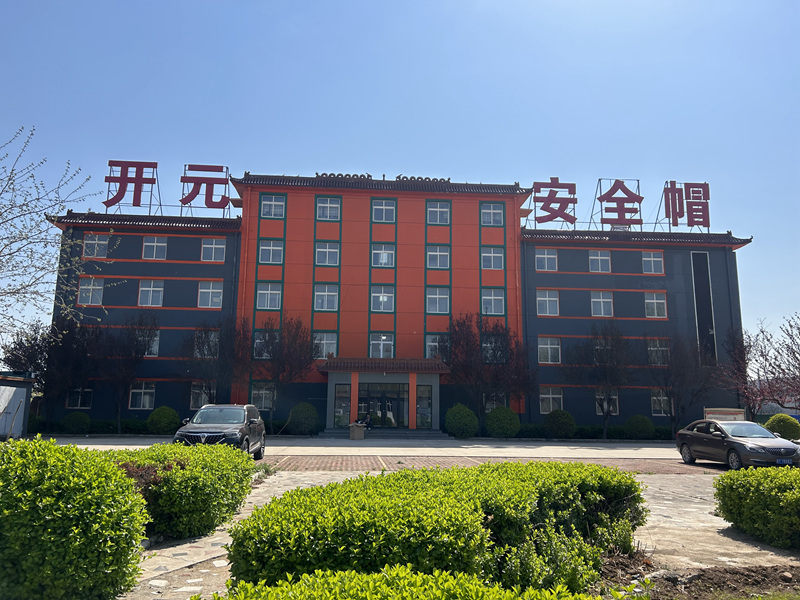

oem lab & safety clothing

The benefits of OEM labs extend beyond safety. By leveraging the expertise found within these facilities, manufacturers can develop innovative safety clothing designs that respond to the unique needs of their workforce. Collaborations between OEM labs and clothing manufacturers can lead to the creation of specialized protective gear that takes into account specific hazards associated with different manufacturing processes. This ongoing development not only improves safety standards but also boosts employee morale and productivity. Workers are more likely to perform effectively if they feel protected and comfortable in their work environment.

Moreover, compliance with safety regulations is mandatory in many industries. Inadequate safety measures can result in severe consequences, including injuries, legal liabilities, and financial losses. Utilizing OEM labs to certify and test safety clothing ensures that manufacturers adhere to industry regulations, thus reducing the risk of non-compliance penalties.

As workplace safety becomes increasingly recognized as a critical component of operational success, the significance of OEM labs and safety clothing will only continue to grow. Companies that prioritize the safety and well-being of their employees not only create a more positive work environment but are also more likely to achieve long-term success. Investing in high-quality safety clothing through collaborations with OEM labs signifies a commitment to workplace safety and operational excellence.

In conclusion, the collaboration between OEM labs and safety clothing manufacturers is essential in today’s manufacturing landscape. This partnership enhances product quality, ensures regulatory compliance, and significantly improves the safety and well-being of workers. As industries evolve and face new challenges, the importance of maintaining high safety standards through innovative solutions will remain a priority for manufacturers worldwide. Fostering a culture of safety not only protects employees but also contributes to the overall growth and sustainability of the organization.

-

Wholesale Safety Helmets - Cheap OEM Supplier China Manufacturer

NewsMay.30,2025

-

Top Safety Helmet Manufacturers in Japan - Durable & Certified

NewsMay.30,2025

-

Affordable 3M Safety Helmets in Pakistan Bulk Pricing & Factory Deals

NewsMay.30,2025

-

Affordable HDPE & EN397 Hard Hats - Safety Certified, Bulk Deals

NewsMay.29,2025

-

FDA-Compliant Food Safety Clothing Suppliers Health Dept Approved

NewsMay.29,2025

-

adidas safety clothing

NewsMar.07,2025